Screens

Spiralift SL

The SPIRALIFT® screens, washes, transports and dewaters solids entrained in the wastewater flow. This system combines the benefits of two proven technologies into one effective system: the SPIRALIFT screening conveying system and a high-performance TASKMASTER® grinder. The processed solids are washed, ground, dewatered and discharged — ideal for landfill disposal, while organics are left in the flow. Because this unit features TASKMASTER grinding technology, it offers the combined benefits of a rugged, effective grinder with enhanced screw screen performance for a uniquely effective and trouble-free system.

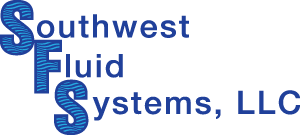

Spiralift SLV

The SPIRALIFT® SLV is a unique fine screen that conveys solids straight up. With its small footprint, it fits into tight places where no other screens can fit. This unit combines TASKMASTER® grinding technology with a vertical screw screen to provide fine screenings of solids entrained in liquid flows.

The SPIRALIFT SLV fits in extremely tight locations such as pump stations’ wet wells. It is typically supplied with a TASKMASTER grinder to pre-condition the solids. After the solids are reduced by the TASKMASTER grinder, they flow into the screen area. The solids are swept from the semicircular perforated screen by brushes mounted on the perimeter of the rotating auger and conveyed vertically up the unit’s transport tube. As the solids are conveyed up the screw, liquids drain back into the flow. An optional compaction zone can be provided for further dewatering.

Spiralift SI

The SPIRALIFT® SI is an inline screening system for wastewater and other liquid entrained solids. This unit is simple in design, reliable and low maintenance. It employs a shaftless screw screen that effectively removes captured solids from the liquid flow. The unit also washes, deodorizes and conveys solids to a convenient discharge point.

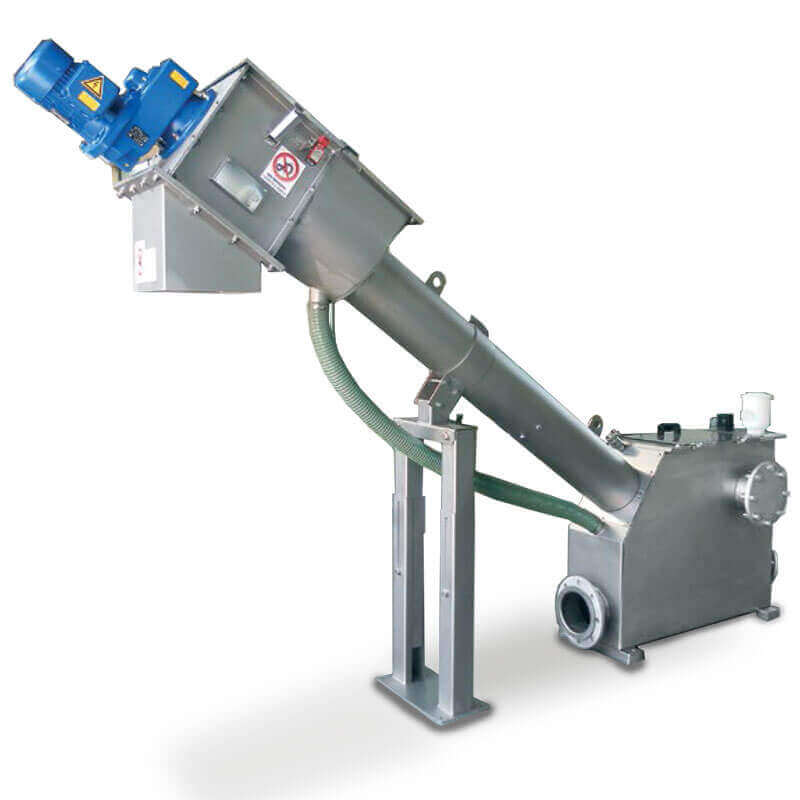

Spiralift SC Screenings Washer / Compactor

The SPIRALIFT® SC Screenings Washer / Compactor provides efficient washing, compacting and deodorizing of screenings. It can be installed behind a new or existing mechanical bar screen installation and quickly goes to work enhancing the screenings output. The processed solids are discharged as ground, uniform particles in a compacted plug, ideally conditioned for disposal. The SPIRALIFT SC washer compactor utilizes a rugged TASKMASTER® Screenings Grinder to reduce solids to a small size exposing multiple surfaces. The ground solids are intensively washed to remove contaminants and organics. The screenings are then compacted and conveyed by unit’s powerful screw press and organics are returned to the flow.

Spiralift SR

The SPIRALIFT® SR Septage Receiving Station is a complete solution for the clean and organized receiving and processing of septage. This complete system along with the Hauler Station control reduces the demand on your system as well as on your personnel.

The SPIRALIFT employs perfected shaftless screw technology to screen the solids from the liquids and then wash and compact the solids. This fully enclosed system features dependable operation, low operating costs and easy installation. These units are provided with between one and four stages of processing to meet a wide variety of application requirements.

The SPIRALIFT SR is provided with an S270-SR Automatic Control System, an optional S270-SRH Hauler Station Control System and a unique TASKMASTER® TT grinder with built-in tramp trap housing.

Screenmaster CS

The SCREENMASTER® CS wastewater bar screen provides efficient cleaning of a bar screen rack and removal of solids from rectangular channel installations. This unit employs a front clean/front return principle. It’s easy to install new or existing channels. The unit installs at a 75° inclination so it has a very small footprint. The design features a simple, continuous rotary motion. As the rake head passes through the bar slots collecting debris, it travels up the unit’s dead plate until it reaches a special scraper supplied with a dash pot for smooth operation. The screenings then drop out of the unit’s discharge chute.

Screenmaster RT

The SCREENMASTER® RT internally fed rotary drum screen employs a rotating drum to provide effective fine screening of a variety of materials with a simple and reliable design. This unit employs a cylindrical screen constructed with perforated metal, wedge wire or filter cloth along with a weir system. As the material is fed into the unit’s inlet, it is distributed along the internal screen surfaces.

As the drum rotates, the weir moves the solids along the screen length. The liquids are discharged out the unit’s bottom. The solids are conveyed to the unit discharge flange. The RT is provided in a choice of models with up to 60” diameter drums up to 156” (4m) in length.