Shredders

Taskmaster TM8500

The TASKMASTER® TM8500 twin shaft shredder is the smallest in the TASKMASTER line of industrial shredders. It features an 8.5” wide cutting chamber up to 60” long and a direct drive. These units feature fully-sealed housing, mechanical shaft seals and patented 5, 7 or 11 tooth cutters. These versatile units are available for gravity feed, open channels or inline service with flanges. The geometry of this dual-shaft cutter also provides excellent feeding characteristics for a variety of solids. TASKMASTER cutters are precision manufactured to exacting standards to provide optimal shredding and long life. Each TASKMASTER shredder is heavily constructed for low deflection or vibration and quiet operation. These versatile shredders can handle screenings, fish waste, fabrics, waste material, and much more.

Taskmaster TM1600

The TASKMASTER® TM1600 industrial shredder is a powerful workhorse that can shred heavy solids in both gravity and liquid systems. This unit can be installed horizontally with a stand, or vertically with a hopper for channel or pipeline applications with flange adapters.

The TM1600 industrial shredder features a fully sealed body housing with 2-3/4″ hardened hex shafting, mechanical seals and direct inline or optional right angle gear drive. Options include: stainless steel construction, enclosed hopper, flange adapters, channel frames, infeed conveyor, discharge washer or compactor, hydraulic drive, space saving right-angle gear drive and more.

Taskmaster TM2300

The TASKMASTER® TM2300 industrial shredder is a heavy-duty shredder designed to reduce a high volume of solids with its low speed, high torque design. This unit is built for the maximum level of performance and reliability using quality components and superior design. Its powerful, direct gear drive reduces the shaft speed and delivers high torque to the cutters for excellent cutting capacity. The unit can rip, tear and shred through a variety of tough solids reducing the volume to strips or chips ideal for further processing or economical disposal.

The TASKMASTER TM2300 industrial shredder is provided standard with 1” thick (25 mm) cam cutters. Other thicknesses and profiles can be provided. The TM2300 housing extends beyond the cutters for enhanced safety and ease of installation in fully enclosed systems.

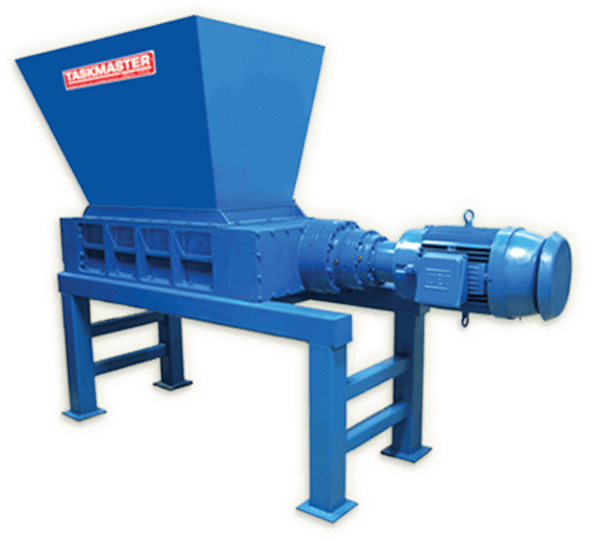

Taskmaster TM3000

The TASKMASTER® TM3000 is a heavy-duty industrial shredder designed to reduce a high volume of solids with its low speed, high torque design. This twin-shaft shredder is suitable for a variety of shredding applications that demand high power, large throat openings and extra heavy-duty construction. The design of this unit provides effective operation with low noise, sparking, dust or heat rise.

The TM3000 is built for the highest level of performance and reliability using quality components, superior design and engineering. It has such heavy construction features as 5.5″ heat-treated alloy steel hexagonal shafting, 2″ cam cutters, heavy steel plate and channel body construction, and planetary gear drive. The unit can rip, tear and shred through a variety of tough solids, reducing the volume for further processing or economical disposal.

Taskmaster TM4000

The TM4000 industrial shredder has such heavy construction features as 7.4″ heat-treated alloy steel hexagonal shafting, 2″ cam cutters, heavy steel plate and channel body construction, and planetary gear drive. The TM4000 can reduce such items as: pallets, steel drums, wood, documents en masse, electronic components, hard drives, hazardous waste, mattresses, solid propellants, plastic sprues and purgings, car light truck and 22.5 size truck tires. These units are provided with a throat opening of 40″ x 54″ (762 mm x 1371 mm) up to 40″ x 72″ (762 mm x 1828 mm).

The TASKMASTER® TM4000 industrial shredder is a heavy-duty industrial shredder designed to reduce a high volume of solids with its low speed, high torque design. This unit is built for the highest level of performance and reliability using quality components, superior design and engineering. Its powerful, direct gear drive reduces the shaft speed and delivers high torque to the cutters. The unit can rip, tear and shred through a variety of tough solids, reducing the volume for further processing or economical disposal.

Taskmaster XL Pallet Shredder

The powerful TASKMASTER XL pallet shredder effectively shreds entire pallets and nails all to reduce their bulk volume. As a result, it can substantially reduce the expense of disposing of pallets. The TASKMASTER XL is supplied complete with stand, hopper and automatic reversing controls. Its streamlined design features a direct coupled gear drive which is smooth running and simple to operate. With the XL, there are no drive belts to re-tension. This unit is designed to be easy to use and easy to maintain. Its hopper automatically directs the pallet into the cutting chamber.

Optional equipment includes auxiliary discharge conveyors to convey the output into a waste container, as well as an available infeed conveyor for a completely automated system.